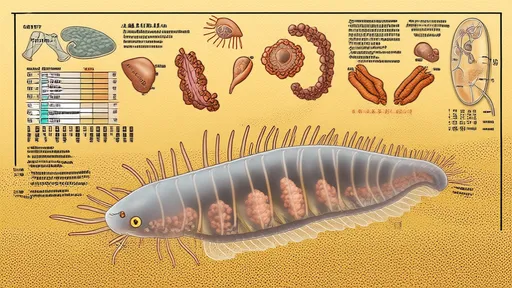

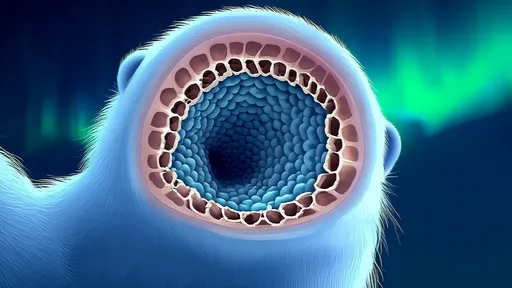

The remarkable thermal insulation properties of polar bear fur have long fascinated scientists and engineers alike. Recent research into the microstructure of polar bear hair has revealed an ingenious natural design: hollow, air-filled medullas that provide exceptional insulation against Arctic cold. These microscopic hollow tubes, invisible to the naked eye, serve as a sophisticated thermal regulation system that outperforms most man-made insulating materials.

At the University of Alaska's Institute of Arctic Biology, Dr. Helena Wickham and her team have developed groundbreaking thermodynamic models to understand how these hollow fibers function. "What appears as simple white fur to the naked eye is actually a complex thermodynamic miracle," explains Dr. Wickham. "Each hair shaft contains multiple microscopic air pockets that create a layered insulation system far more efficient than solid fibers." The team's computational models simulate heat transfer through these hollow structures under various environmental conditions.

The research reveals that the hollow structure creates a thermal buffer zone where heat transfer occurs in stages rather than directly. As body heat attempts to escape through the hair, it must navigate a series of air-filled chambers that dramatically slow conductive heat loss. Meanwhile, the translucent nature of the hair shafts allows for optimal solar heat absorption while minimizing radiative heat loss - a perfect adaptation for an animal that thrives in below-freezing temperatures.

Engineers at MIT's Department of Materials Science have begun applying these findings to develop advanced insulating materials. Preliminary tests show that synthetic fibers mimicking polar bear hair structure can provide up to 30% better insulation than current high-performance materials while being significantly lighter. Potential applications range from Arctic expedition gear to energy-efficient building insulation that could dramatically reduce heating costs in cold climates.

What makes polar bear fur particularly remarkable is its dynamic response to environmental changes. The hollow fibers appear to adjust their insulating properties based on humidity and temperature fluctuations. During physical activity when the bear generates excess heat, the microstructure facilitates slightly increased heat dissipation to prevent overheating. Conversely, when the animal rests in subzero temperatures, the insulation becomes more efficient. This adaptive capability has inspired researchers to develop "smart" insulating materials that can automatically adjust their properties.

The commercial implications of this research are substantial. Outdoor apparel companies are already investing heavily in developing jackets that replicate polar bear fur's hollow fiber structure. Unlike down insulation which loses effectiveness when wet, or synthetic fills that can be bulky, polar bear-inspired materials promise lightweight, water-resistant insulation that maintains thermal properties in diverse conditions. Prototypes have shown particular promise for extreme cold weather gear where weight and performance are critical factors.

Beyond clothing applications, the architecture industry sees potential in building insulation. The hollow fiber structure could lead to thinner yet more effective wall insulation, allowing for increased interior space without sacrificing energy efficiency. Some researchers speculate that scaled-up versions of this microstructure might even find applications in spacecraft insulation or cryogenic storage systems where minimizing heat transfer is crucial.

As research continues, scientists are discovering additional benefits of the hollow fiber structure. The air pockets appear to provide acoustic damping properties, suggesting potential applications in soundproofing materials. There's also evidence that the microstructure contributes to the fur's characteristic water-shedding ability, keeping polar bears dry despite frequent swimming in icy waters. Each new discovery adds to the growing appreciation of this natural engineering marvel.

The study of polar bear fur represents a perfect example of biomimicry - the practice of learning from and emulating nature's solutions to complex engineering challenges. As Dr. Wickham notes, "After millions of years of evolution, polar bears have perfected thermal insulation in ways we're only beginning to understand." Her team's thermodynamic models continue to reveal new insights about how these hollow fibers achieve such remarkable performance, providing a blueprint for next-generation insulating materials.

Looking ahead, researchers anticipate that polar bear-inspired materials could play a significant role in addressing energy efficiency challenges. With buildings accounting for nearly 40% of global energy consumption, improved insulation technologies based on this natural design could have substantial environmental benefits. Similarly, more efficient cold-weather gear could reduce energy demands for heating in everything from Arctic research stations to winter sports facilities.

The journey from Arctic wildlife observation to advanced material science demonstrates the unexpected connections between biology and engineering. As scientists continue to decode nature's sophisticated designs, they're finding that solutions to many human challenges may have been hiding in plain sight - or in this case, in the shimmering white coat of the Arctic's most iconic predator. The humble polar bear hair, it turns out, holds lessons that could help humanity better insulate itself against an increasingly uncertain climate future.

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025