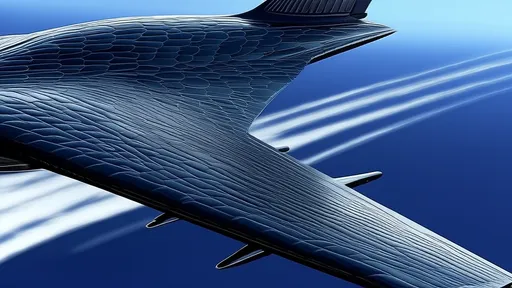

For decades, aerospace engineers have sought ways to reduce drag and improve fuel efficiency in aircraft. One of the most promising breakthroughs comes from an unlikely source: the skin of sharks. Researchers have discovered that the microscopic texture of shark skin holds the key to manipulating airflow over aircraft wings, potentially revolutionizing turbulence control in aviation.

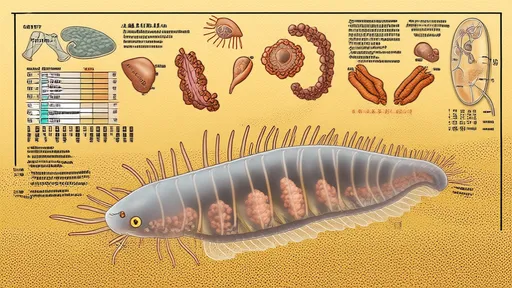

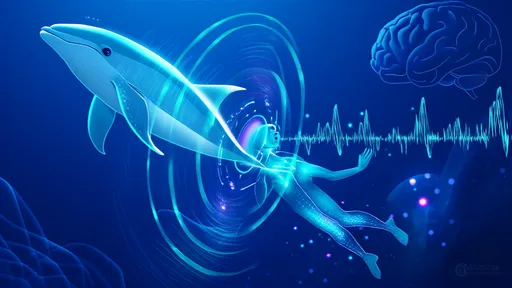

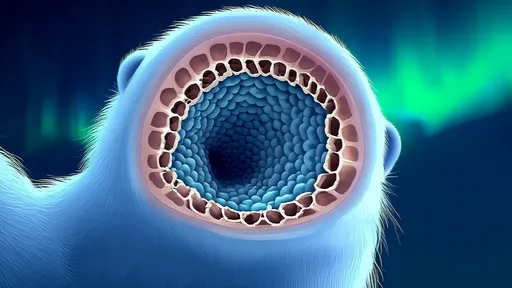

The concept isn't entirely new. Marine biologists have long known that shark skin possesses unique hydrodynamic properties. Unlike smooth surfaces, shark skin contains millions of microscopic tooth-like structures called denticles. These denticles create a complex pattern of grooves that interact with water flow in remarkable ways, reducing drag and preventing turbulent vortices from forming.

From Ocean to Sky: Translating Nature's Design

When applied to aircraft, this biomimetic approach involves creating specialized coatings with precisely engineered micro-grooves. These grooves, typically measuring between 50-200 microns in width (about the thickness of a human hair), run parallel to the direction of airflow. Their presence creates what scientists call a "riblet effect," subtly altering how air molecules interact with the wing's surface.

The physics behind this phenomenon is fascinating. The micro-grooves effectively trap a thin layer of air close to the surface, creating a buffer zone between the wing and the turbulent outer airflow. This trapped layer moves with the wing, reducing the velocity gradient between the stationary surface and moving air. The result is a significant reduction in skin friction drag - often by as much as 8-10% in controlled tests.

Manufacturing Challenges and Breakthroughs

Creating these microscopic surface patterns at scale presented significant engineering hurdles. Early attempts used expensive laser etching techniques that proved impractical for large-scale aircraft production. However, recent advancements in roll-to-roll manufacturing and specialized polymer films have made the technology more viable.

One particularly promising development involves self-assembling polymer coatings that naturally form the required groove patterns when applied and cured. These "smart coatings" can be sprayed or rolled onto existing wing surfaces, potentially allowing retrofitting of current aircraft fleets without major structural modifications.

Flight Test Results and Commercial Potential

Several major aerospace manufacturers have conducted extensive flight tests with micro-groove coatings. Initial results show not only reduced fuel consumption (typically 1-2% in real-world conditions) but also unexpected benefits like decreased ice accumulation and reduced noise from wing turbulence.

The commercial implications are substantial. For a typical mid-sized airliner, even a 1% reduction in fuel burn translates to annual savings of hundreds of thousands of dollars per aircraft. When multiplied across global fleets, the potential economic and environmental impact becomes enormous.

Beyond Aviation: Broader Applications

While aircraft applications have drawn the most attention, shark skin-inspired coatings are finding uses in other fields. Wind turbine manufacturers are experimenting with similar textures on blade surfaces to increase energy capture. The automotive industry sees potential for more efficient vehicle designs. Even the maritime sector is exploring applications for ship hulls to reduce biofouling and improve hydrodynamics.

Perhaps most intriguing are potential medical applications. Researchers are studying whether similar micro-patterns could reduce bacterial growth on hospital surfaces or improve the performance of vascular implants by manipulating blood flow patterns.

Future Developments and Research Directions

The next generation of these coatings may incorporate adaptive features. Imagine surfaces where the micro-grooves can change their orientation or depth in response to airflow conditions, temperature, or other environmental factors. Such "active" surfaces could optimize their performance throughout different phases of flight or under varying weather conditions.

Other research focuses on combining the micro-groove approach with other drag-reduction technologies like laminar flow control or boundary layer suction. These hybrid systems could potentially deliver even greater efficiency gains than any single approach alone.

As with any emerging technology, challenges remain. Durability testing under real-world conditions (including exposure to UV radiation, extreme temperatures, and mechanical wear) continues. Regulatory approval processes for new aviation technologies are notoriously rigorous. And the aerospace industry, with its emphasis on proven reliability, tends to adopt new technologies cautiously.

Nevertheless, the potential benefits make shark skin-inspired coatings one of the most exciting developments in aerodynamic engineering in recent years. As research progresses and manufacturing techniques improve, we may soon see entire aircraft covered in surfaces that owe their design to one of nature's most efficient swimmers.

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025