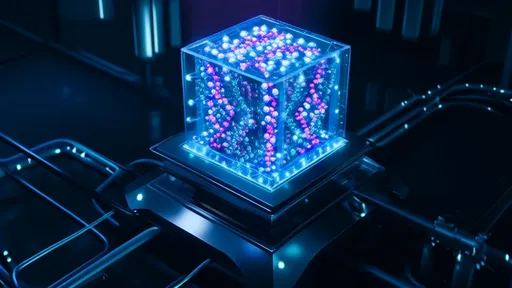

The field of regenerative medicine has taken a revolutionary leap forward with the advent of 4D bioprinting, a cutting-edge technology that combines the precision of 3D printing with the dynamic responsiveness of shape-memory materials. At the heart of this innovation lies the concept of shape-memory scaffolds, which are designed to guide the self-assembly of cells into functional tissues and organs. Unlike traditional 3D-printed structures, these scaffolds can transform over time in response to physiological cues, mimicking the natural development of biological tissues.

Researchers have long struggled to replicate the complexity of human organs, which are not static but evolve through intricate processes of cell migration, differentiation, and matrix remodeling. 4D bioprinting addresses this challenge by introducing a temporal dimension to tissue engineering. The scaffolds are fabricated using smart materials that "remember" their original shape and can revert to it when triggered by specific stimuli, such as temperature changes or chemical signals. This dynamic behavior enables the scaffold to direct cellular organization in a way that closely resembles native tissue formation.

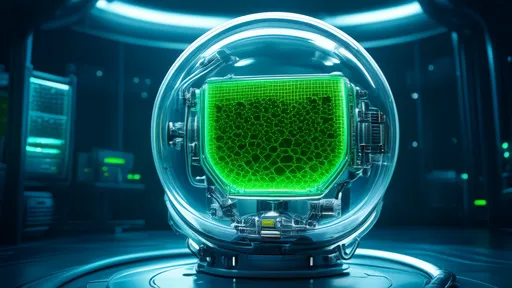

The potential applications of this technology are vast, ranging from personalized organ transplants to advanced drug testing platforms. For instance, a liver scaffold could be printed to initially assume a compact shape for easy implantation, then expand and remodel itself within the body to match the patient's anatomy. Similarly, cardiac patches could be designed to contract and relax in sync with the heart's natural rhythm, offering new hope for patients with severe heart damage.

One of the most exciting aspects of shape-memory scaffolds is their ability to facilitate self-assembly—a process where cells autonomously organize into functional structures. By providing a dynamic framework that changes in harmony with cellular activity, these scaffolds create an environment where cells can interact and arrange themselves as they would during natural tissue development. This stands in stark contrast to traditional static scaffolds, which often fail to fully replicate the dynamic nature of biological systems.

Recent breakthroughs have demonstrated the feasibility of this approach. Scientists have successfully printed tracheal implants that gradually change shape to match the patient's airway, as well as vascular grafts that adapt to blood flow patterns. These achievements underscore the transformative potential of 4D bioprinting in overcoming the limitations of conventional tissue engineering methods.

However, significant challenges remain before this technology can be widely adopted in clinical settings. The long-term biocompatibility of shape-memory materials must be thoroughly evaluated, and the precision of 4D printing techniques needs further refinement to ensure consistent results. Additionally, researchers must develop robust methods for controlling the timing and extent of scaffold transformations to avoid unintended consequences in vivo.

Despite these hurdles, the progress in 4D bioprinting represents a paradigm shift in regenerative medicine. By harnessing the power of shape-memory materials and cellular self-assembly, scientists are inching closer to the holy grail of creating fully functional, lab-grown organs. As the technology matures, it could fundamentally alter how we treat organ failure and degenerative diseases, offering patients safer and more effective alternatives to traditional transplants.

The intersection of materials science, biology, and engineering in this field is yielding unprecedented insights into tissue development and repair. Each advancement brings us closer to a future where organ shortages are a thing of the past, and personalized, bioengineered tissues are readily available to those in need. The journey from concept to clinical reality may be long, but the promise of 4D bioprinting makes it a path worth pursuing with relentless dedication.

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025